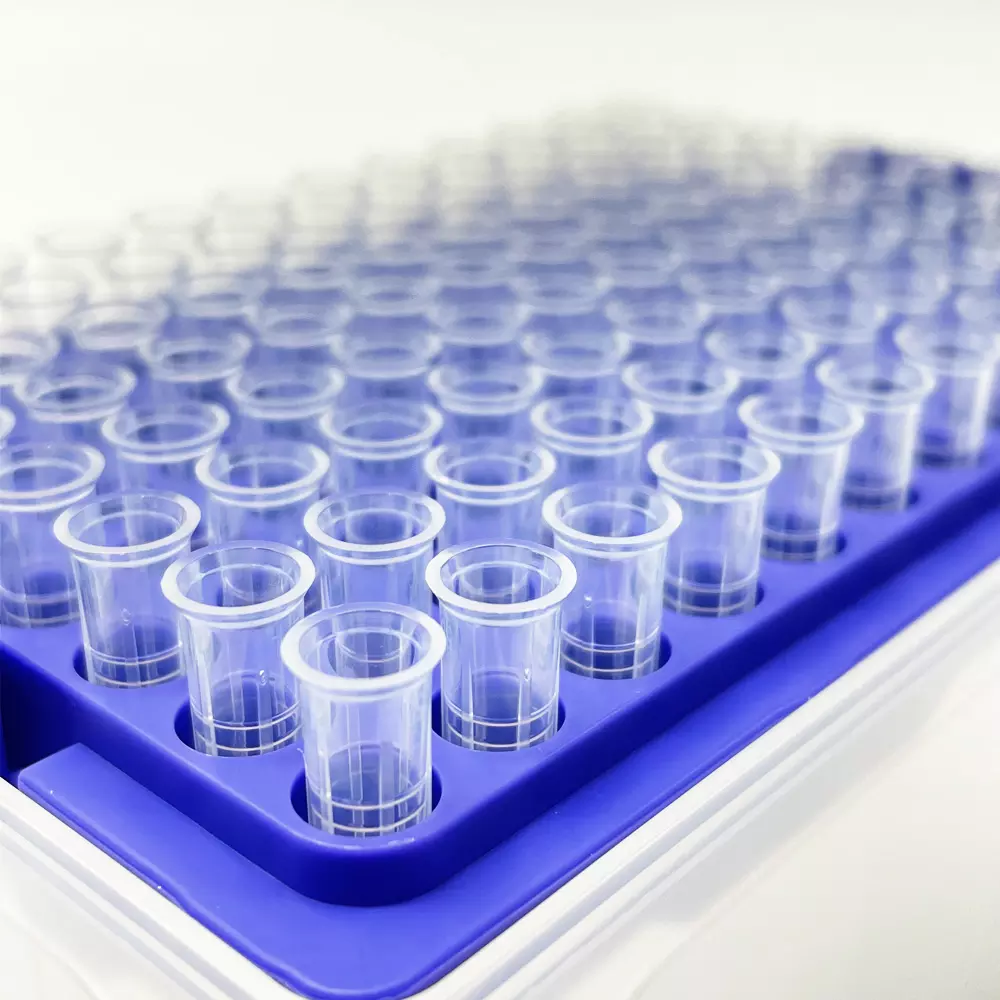

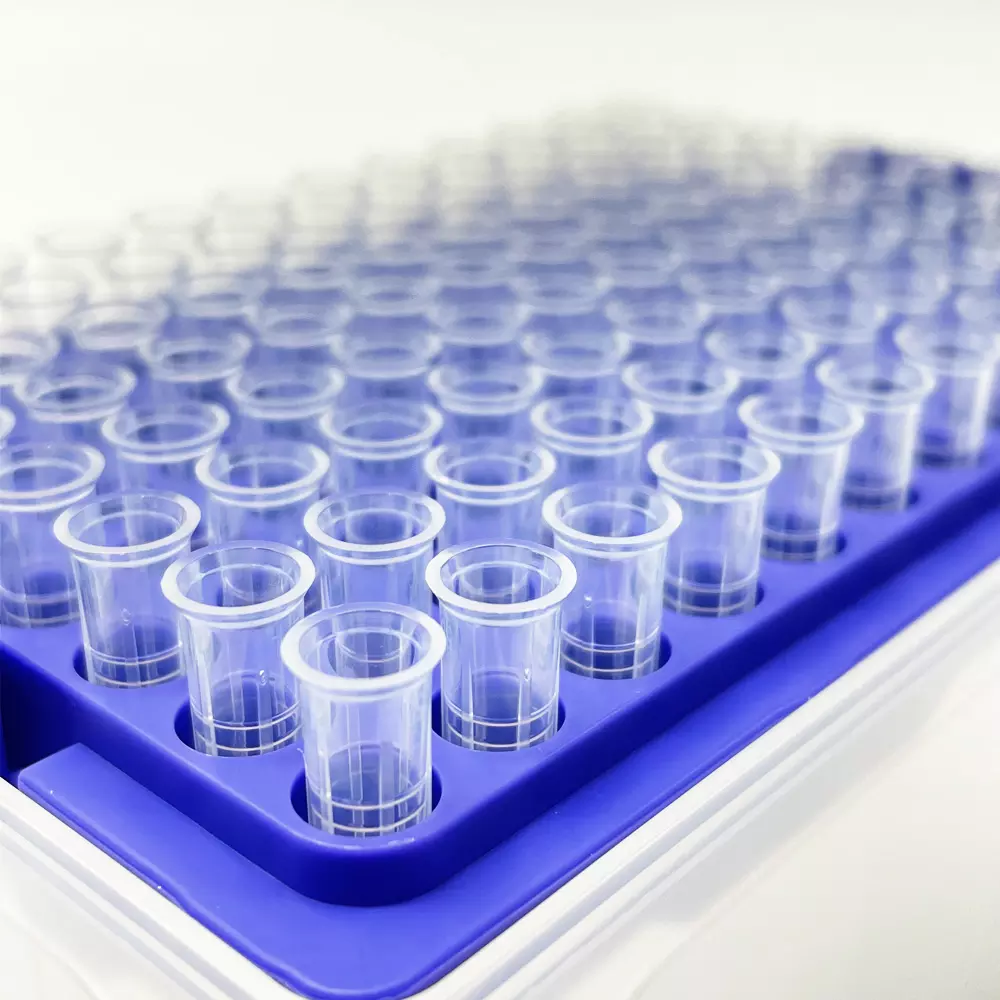

Classification of Pipette Tips

As consumables used in conjunction with pipetting devices, pipette tips can be generally divided into standard tips, filter tips, low retention tips, automated tips and other types according to their different applications. Standard tips are the most widely used pipette tips, and they, which are considered as the most economical type of tips, can be universally fit for almost all pipetting operations. Filter tips are laboratory consumables designed to avoid cross-contamination. Samples taken by filtered tips can't enter the inside of pipettes, so as to protect their parts from contamination and corrosion, and more importantly, to ensure that there is no cross-pollution among samples. Filtered pipette tips are often applied in experiments such as molecular biology, cytology and virology.

For experiments with high sensitivity, or precious samples or reagents that are easy to remain, low-retention tips can be selected to improve the recovery. And the surface of low retention tips is hydrophobic, reducing the liquid residue in the pipette tips. Robotic tips are mainly compatible with automated liquid handling workstations, including Tecan, Hamilton, Beckman and Agilent. With the large-scale outbreak of the COVID-19 epidemic, domestic workstations are also rapidly developing.

Factors that may affect the quality of pipette tips

1. Material

At present, pipette tips on the market are basically made of polypropylene (PP), a kind of transparent plastic with high chemical inertness and a wide service temperature range. High-quality tips are usually made of natural polypropylene, while low-cost tips are probably made of recycled polypropylene plastics. We manufacture pipette tips with superior imported polypropylene material that has high transparency and resistance to organic solvents. It also possesses excellent performance with -80℃ - 121℃ temperature tolerance and no deformation under high pressure and high temperature.

2. Additives

A small number of additives would be added in the manufacturing process of many pipette tips. The common additives include chromogenic materials for blue and yellow pipette tips, additives that can help the pipette tip to quickly separate from the mold after forming, and additives for treating the surface of low binding pipette tips. The more additives people use, the higher the probability of occurring undesirable chemical reactions in the pipetting process. However, it's difficult for manufacturers to ensure there is no additive in the production process. As a high-tech enterprise with years of experience, we adopt advanced molding technology and strict quality control to guarantee the optimal performance of products and minimal liquid residue.

3. Biological Pollution

More and more users are looking for pipette tips with no DNase, RNase, pyrogen and endotoxin. However, the tips sterilized at high temperatures can't completely keep away from biological pollution. To ensure no biological pollution, gamma-ray treatment and other steps are needed. Therefore, it is almost impossible for users to treat ordinary tips into tips without bio-contamination. We have 100000-class dust-free workshops to ensure that the products are free of pyrogen, DNase, RNase and endotoxin.

As consumables used in conjunction with pipetting devices, pipette tips can be generally divided into standard tips, filter tips, low retention tips, automated tips and other types according to their different applications. Standard tips are the most widely used pipette tips, and they, which are considered as the most economical type of tips, can be universally fit for almost all pipetting operations. Filter tips are laboratory consumables designed to avoid cross-contamination. Samples taken by filtered tips can't enter the inside of pipettes, so as to protect their parts from contamination and corrosion, and more importantly, to ensure that there is no cross-pollution among samples. Filtered pipette tips are often applied in experiments such as molecular biology, cytology and virology.

For experiments with high sensitivity, or precious samples or reagents that are easy to remain, low-retention tips can be selected to improve the recovery. And the surface of low retention tips is hydrophobic, reducing the liquid residue in the pipette tips. Robotic tips are mainly compatible with automated liquid handling workstations, including Tecan, Hamilton, Beckman and Agilent. With the large-scale outbreak of the COVID-19 epidemic, domestic workstations are also rapidly developing.

Factors that may affect the quality of pipette tips

1. Material

At present, pipette tips on the market are basically made of polypropylene (PP), a kind of transparent plastic with high chemical inertness and a wide service temperature range. High-quality tips are usually made of natural polypropylene, while low-cost tips are probably made of recycled polypropylene plastics. We manufacture pipette tips with superior imported polypropylene material that has high transparency and resistance to organic solvents. It also possesses excellent performance with -80℃ - 121℃ temperature tolerance and no deformation under high pressure and high temperature.

2. Additives

A small number of additives would be added in the manufacturing process of many pipette tips. The common additives include chromogenic materials for blue and yellow pipette tips, additives that can help the pipette tip to quickly separate from the mold after forming, and additives for treating the surface of low binding pipette tips. The more additives people use, the higher the probability of occurring undesirable chemical reactions in the pipetting process. However, it's difficult for manufacturers to ensure there is no additive in the production process. As a high-tech enterprise with years of experience, we adopt advanced molding technology and strict quality control to guarantee the optimal performance of products and minimal liquid residue.

3. Biological Pollution

More and more users are looking for pipette tips with no DNase, RNase, pyrogen and endotoxin. However, the tips sterilized at high temperatures can't completely keep away from biological pollution. To ensure no biological pollution, gamma-ray treatment and other steps are needed. Therefore, it is almost impossible for users to treat ordinary tips into tips without bio-contamination. We have 100000-class dust-free workshops to ensure that the products are free of pyrogen, DNase, RNase and endotoxin.

Next: 2021 Exhibition Information