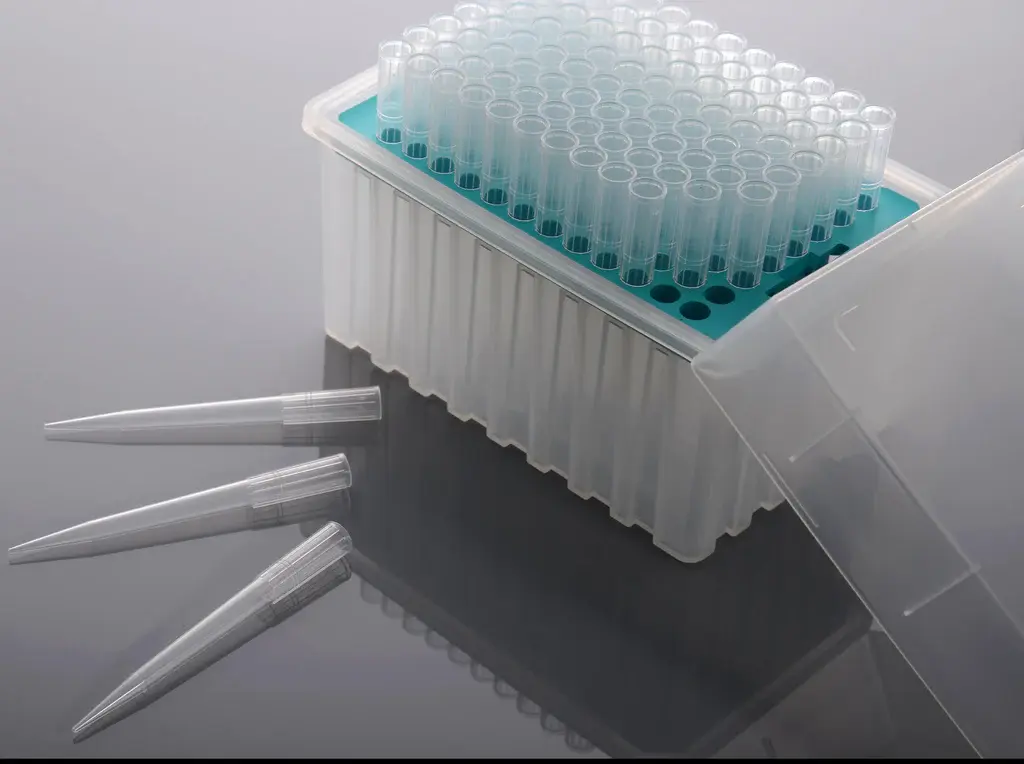

There has been a surge in demand for pipette tips in biological testing laboratories, which is now tenfold higher compared to previous years. Pipette tips play a crucial role in chemical and molecular biology analyses. Operating on the principle of a piston, pipettes enable precise sampling and dispensing of liquids.

Traditionally, pipettes are fitted with tips at their lower ends. These removable components are designed to collect samples for molecular biology and genetic research, providing a protective barrier between the pipette and the sample, thus ensuring sample integrity. Typically made from disposable polypropylene, pipette tips are packaged sterile and tailored to the nature of the samples being handled.

During use, a thin liquid film often coats the inner walls of pipette tips. Upon disposal, this film leads to the wastage of significant volumes of valuable samples, particularly in sensitive PCR and real-time quantitative PCR experiments. Low adsorption surfaces improve repeatability and minimize the loss of costly reagents. Surface treatments, such as super-hydrophobic nano-coatings, significantly reduce liquid adsorption, offering superior performance compared to untreated polypropylene surfaces.

In response to the 2021 EU REACH Act banning C8-based chemical coatings, halogen-free alternatives like Nanofics and PlasmaGuard have emerged as compliant solutions. Market recognition has been swift, with many leading experimental consumables manufacturers in Europe and America adopting these coatings.

Key Features of Super-Hydrophobic Nano Coatings:

1. Even coating on complex surfaces or structures.

2. Ultra-thin 3D plasma flexible coating, ranging from 50 to 500nm in thickness.

3. High-temperature resistance, withstanding up to 159℃.

4. Reduced liquid adsorption, minimizing sample loss.

5. Antibacterial and biocompatible properties, meeting REACH, ROHS, USP, and WEEE standards.

6. Available in both ordinary and halogen-free variants, meeting the latest EU REACH Act requirements.

Europlasma employs low-pressure plasma surface polymerization (PECVD) or atomic layer deposition under vacuum conditions to apply nano-coatings to shallow material surfaces. This process endows materials with new functionalities without compromising their performance. Europlasma's plasma nano-coatings adhere to REACH, RoHS, and WEEE standards, offering uniform coverage on three-dimensional structures and complex shapes.

Next: Tips for Extending the Lifespan of Pipettes

Previous: Pulse Biological News about Pipette Tips